Gauge Reviewer

Application for quality control

Project Overview

- Project Name : Gauge Reviewer

- Version : v1.0

- Last Modified : 09.10.2024

Thank you for taking the time to visit the Gauge Reviewer project! The Gauge Reviewer project was designed for the quality control department, specifically for the sub-division responsible for setting up and preparing measurement instruments for production lines. This system enables the monitoring of which gauges have been issued, when they were issued, and tracks their usage. Additionally, it allows users to schedule and receive notifications about upcoming gauge inspections, ensuring that the necessary checks are carried out by the appropriate personnel.

Technology Stack

The application features an integrated SQLite database that stores all necessary data regarding machine operation times, gauge issuance, and inspection schedules.

The backend is built using Node.js, providing a robust platform for handling data processing and server-side operations, while the frontend is developed using HTML, CSS, and JavaScript, ensuring a user-friendly and responsive interface.

Application Functionalities

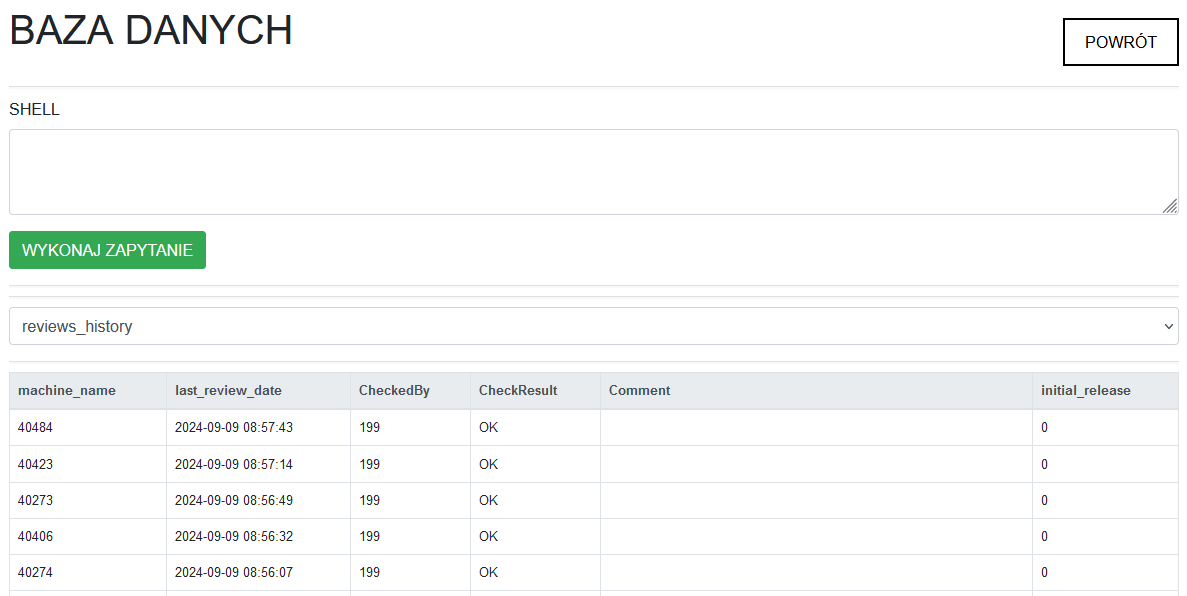

Database Search and Shell

The application includes a database search functionality, allowing users to display selected tables and use a built-in shell to execute SQL commands directly.

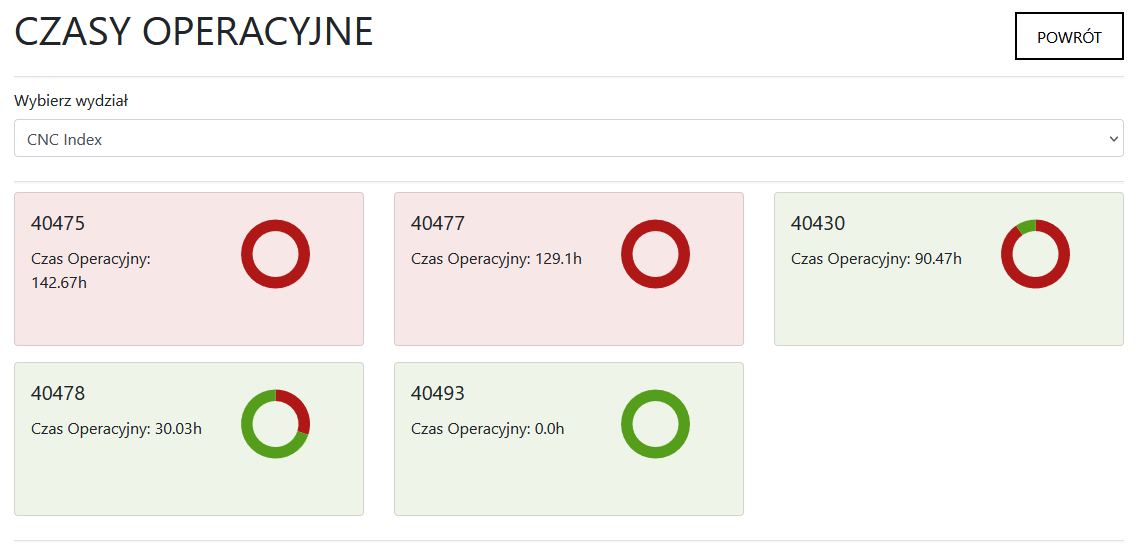

Machine Operation Time Monitoring

The application provides an overview of machine operation times from selected departments, enabling users to check whether a specific set of gauges requires inspection.

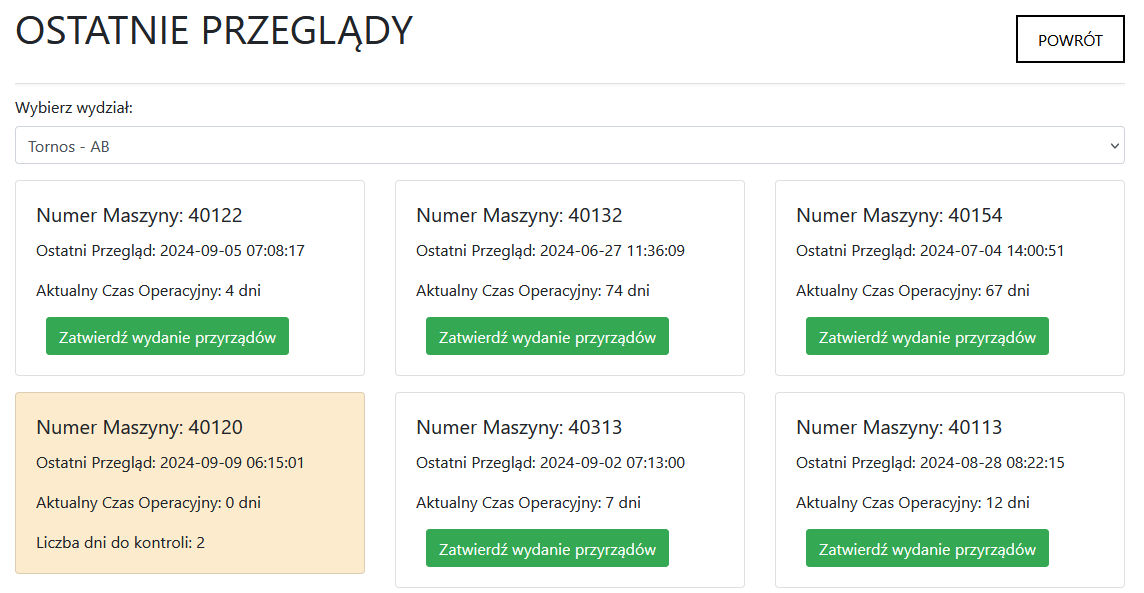

Inspection Tracking and Approval

The system tracks the times of the last inspections and allows users to approve inspections. It also displays the remaining time until the next inspection and enables workers to confirm completed inspections.

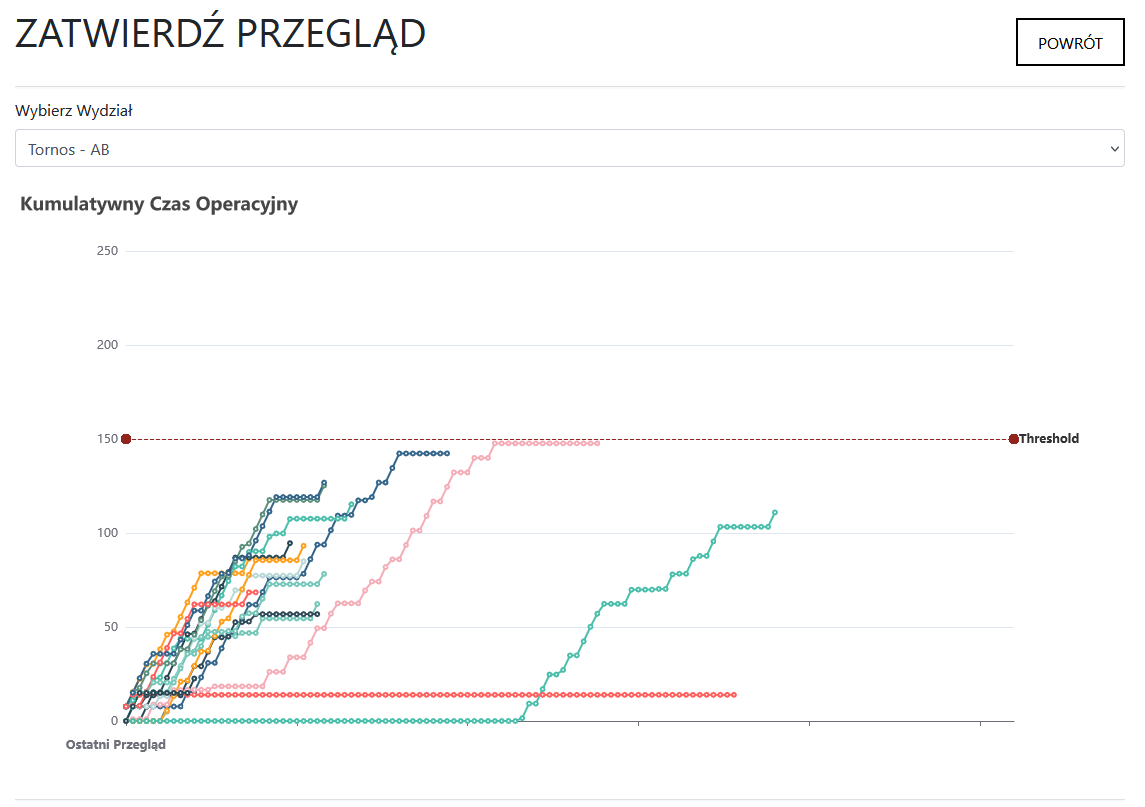

Visual Representation of Machine Operation

The application visually represents hourly machine operation and sets thresholds. When these thresholds are exceeded, the associated set of gauges must be inspected. The interactive chart allows users to explore machine operation data in detail. In such cases, the application generates forms for approving completed inspections.

The application has centralized the entire process of monitoring measurement gauges, which was previously managed manually using paper records. Now, users have precise information on where and when inspections need to be performed, greatly improving efficiency and accuracy in maintaining equipment.